Are you interested in our solutions? Then write us a message. Our sales team will be happy to help you.

Start enquiryOur products and services are intended to inspire people, improve their quality of life, and conserve natural resources. And we place the highest demands on ourselves when it comes to quality and reliability. In short, we create technology that is “Invented for life.” The long tradition of Bosch Mobility shows not only who we are but also where our future might take us. Explore the many innovations from our 125-year company history.

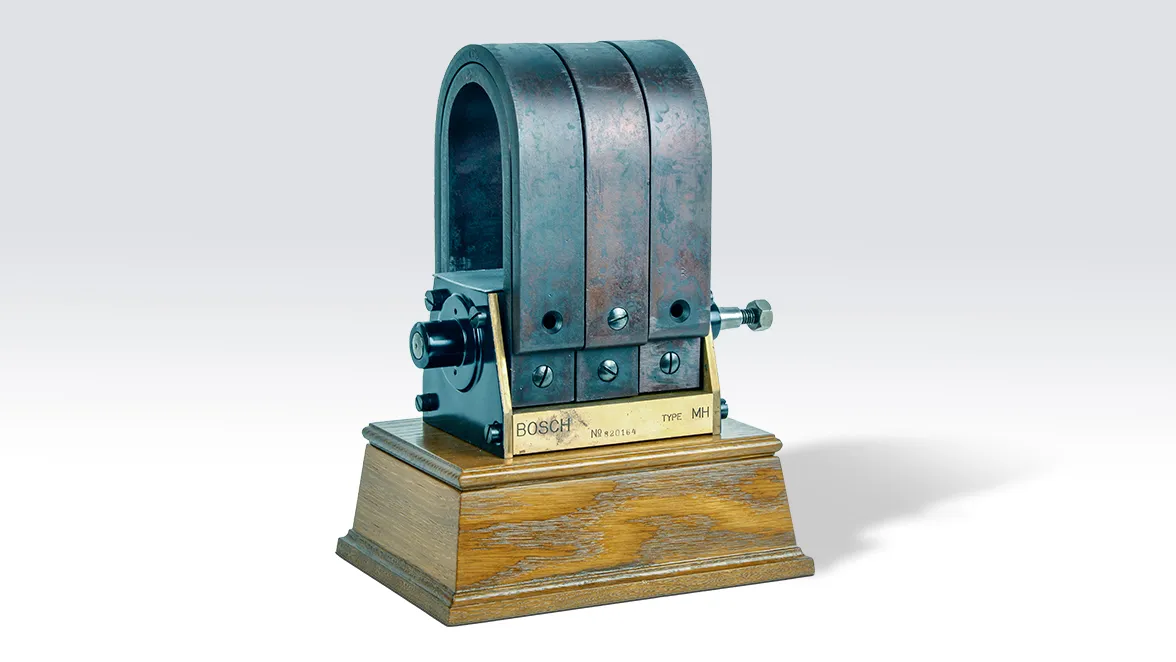

In 1897, the “Bosch magneto ignition” was a pioneering, high-tech product that was completely without precedent – and suitable for volume production. Automotive manufacturers now finally had access to ignition systems that would make the automobile a realistic means of everyday transportation. This new product paved the way for the transformation of Robert Bosch’s courtyard-entrance workshop into a global corporation.

In the summer of 1901, Robert Bosch commissioned his associate Gottlob Honold with the construction of a magneto ignition without the usual, high-maintenance break-spark rodding. Just a few months later, Honold unveiled the high-voltage magneto ignition – or electric arc ignition, as it was also known. It generated a high-voltage current by means of two coils on the armature. Using a simple cable connection, this current was conducted to a spark plug, the electrodes of which formed the all-important spark.

In 1909, Robert Bosch concluded a contract with Eugen Wörner from Cannstatt near Stuttgart, allowing him to construct central lubricating devices – known as “oilers” – for use in engines. The knowledge that Robert Bosch gained from the oiler technology, specifically regarding the management of high pressures and accurate metering of fluids, proved essential in the development of injection systems for diesel and gasoline engines – a field in which Bosch is now a global market leader.

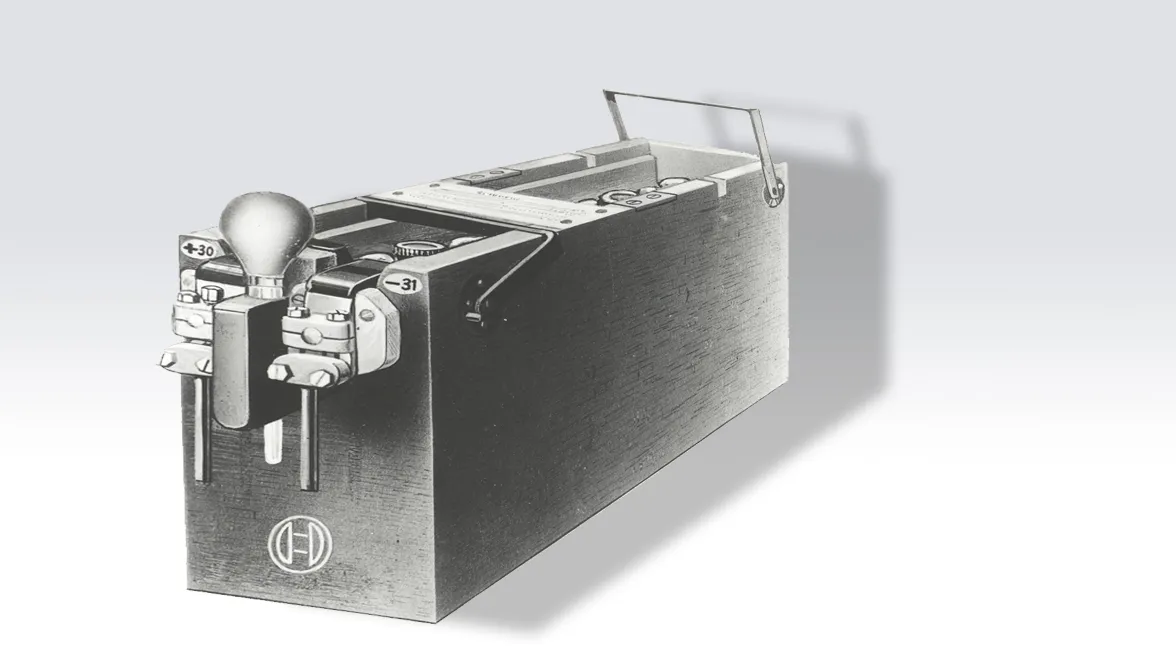

Development work on the generator commenced in 1910, and the “Bosch automotive lighting system” was ready for volume production in 1913. The system comprised the generator, headlights, battery, and voltage regulator. This electrical system represented Bosch’s first step on the road to becoming an automotive supplier and laid the foundation for today’s vehicle electrical systems.

Electric starters made life much easier for drivers. It spared chauffeurs the strenuous task of cranking the car, and the number of “self-drivers” increased significantly as a result. Another factor was that the cranking procedure could be quite dangerous since the crank handle had a tendency to kick back. The electric starter, on the other hand, was safe and easy to operate.

The “Bosch horn” replaced the squeaky, hand-operated bulb horns, terrifying klaxons and other ear-splitting solutions that were usual at the time. It was based on the “closed pipe” principle used in the world of organ building. The result was a pleasant sound with a range of more than one kilometer – and a design principle that remains the established standard to this day.

The first Bosch vehicle electrical systems featured lighting, a generator, and a regulator – all manufactured in-house. The battery, however, was initially procured externally. Only in 1922 did Bosch start manufacturing its own batteries with the aim of ensuring consistent quality levels and to allow the company to offer a complete solution from a single source.

Consisting of an electric motor that powered a rubber-coated lever arm via a worm screw and gear, the electric windshield wiper from Bosch finally ensured a clear view ahead in rainy or snowy conditions.

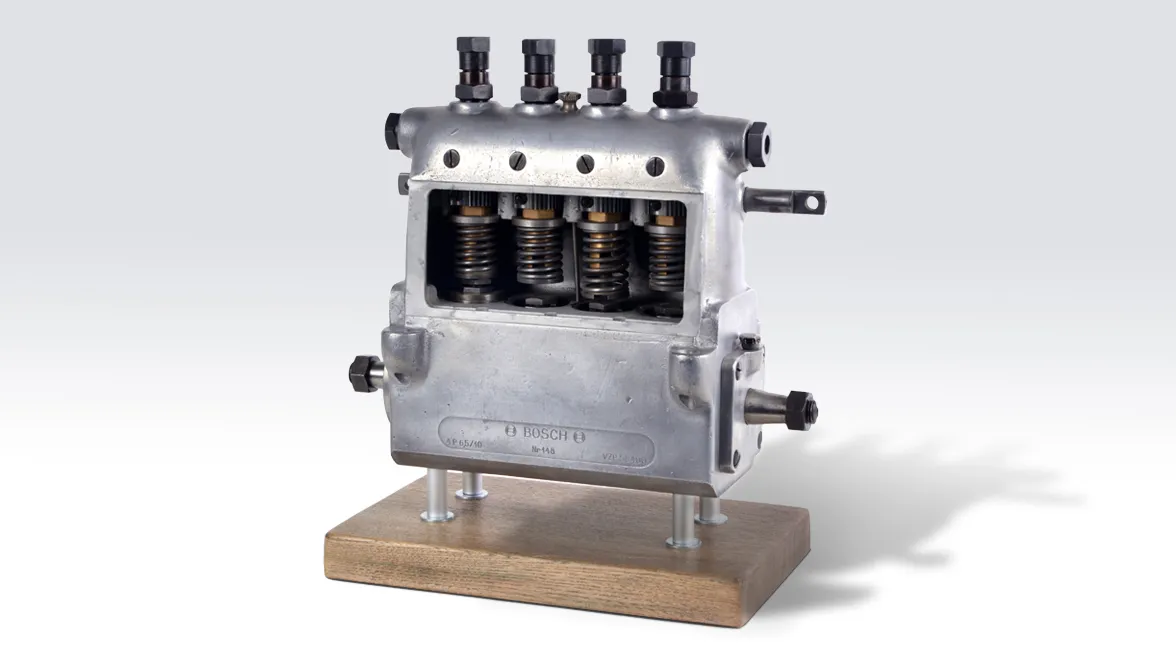

The PE4 diesel injection pump constructed in 1927 made commercial vehicles economical. The approximately 1,000 pumps manufactured during the winter of 1927 and 1928 laid the foundation for the present success of the Bosch diesel segment.

The brake was, without doubt, the first and most important of all vehicle safety components. As early as the 1920s, however, automotive brakes were barely able to cope with the engine power and weight of vehicles in use at the time. The pneumatic servo brake introduced by Bosch in 1927 delivered a significant boost in safety. This ingenious invention reduced the braking distance of commercial vehicles by no less than a third.

The direction indicator from Bosch consisted of an electromagnet, which caused the indicator arm to swing out of its housing when the indicator switch was operated. The indicator arms was also illuminated by a light bulb so that it was clearly visible in the dark.

In the 1930s Bosch supplemented its very successful lighting portfolio with other special applications such as fog lights, long-range lights, rear lights, and brake lights. Bosch went on to become the world’s leading manufacturer of vehicle lighting.

The radio experts from Ideal worked with the automotive electrics specialists from Bosch in Stuttgart to develop Europe’s first volume-production car radio. It was called “Auto-Super 5” and carried the blue dot (or “Blauer Punkt”) that would remain the company and brand name for Bosch consumer electronics until as recently as 2009. This massive metal device weighed 12 kilograms and was very difficult to accommodate in the passenger footwell.

As a rule, cars produced in the 1930s did not feature heating as standard. This made the Bosch car heating system a welcome source of warmth when retrofitted to vehicles. It also helped to defog windows providing a clear vision. The electric heating fan was fitted below the dashboard, usually in front of the passenger. From here, the warm air traveled through hoses to the front windshield where it was drawn up along the glass.

In 1951, Bosch presented its gasoline injection system at the German International Motor Show (IAA) in Frankfurt, specifically in a two-stroke Gutbrod Superior 600 and a Goliath GP 700. With its precise fuel metering, the system reduced the vehicle’s fuel consumption by around 20 percent, while also increasing its power output – from 23 to 28 horsepower in the case of the Gutbrod. In four-stroke engines, which were first used in the Mercedes-Benz 300 SL (“Gullwing”), the significant power gains delivered by the gasoline injection system served as one of the main selling points.

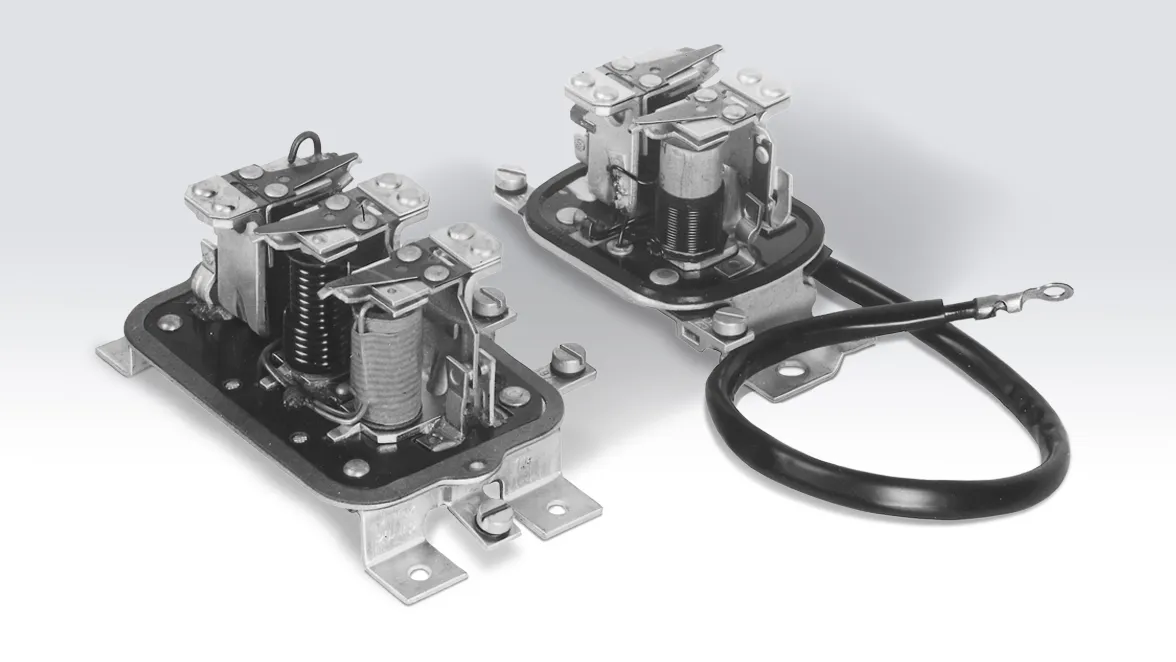

The semiconductor element known as the “variode”, which went into volume production in 1958, was a fairly plain and unimpressive component – barely the size of a pea and indistinguishable on the photo of a generator regulator. Yet this innovative product ensured better and more uniform charging of the battery by the generator, particularly when idling in stationary traffic. This component sowed the first seed in the field of electronics, which is now a key area of business for Bosch.

The new generation of the three-phase-current alternator generated sufficient electrical energy for charging the battery during engine idle. This innovation was necessitated by the slow-moving traffic and tailbacks attributable to the ever-increasing amount of cars on the roads, not least because the generator had to provide more energy to supply the growing number of consumers installed in vehicles.

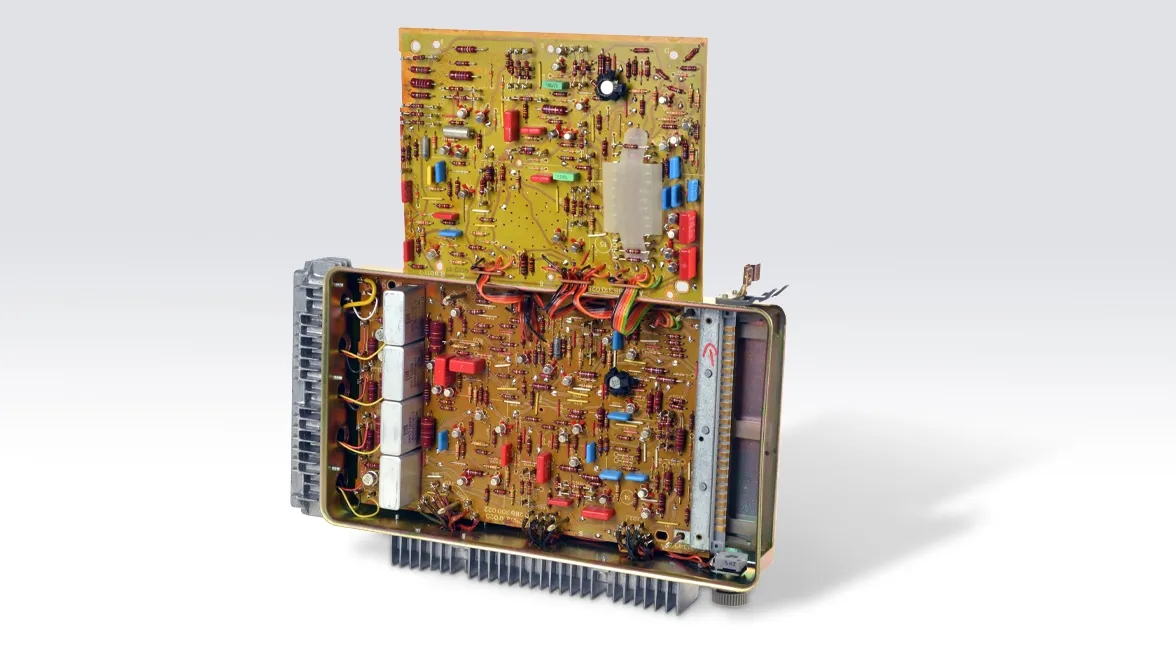

In 1967, Bosch unveiled the electronically controlled “Jetronic” at the IAA in Frankfurt. It was first launched in the United States to satisfy the strict new emissions standards in the important market of California.

In 1971, Bosch introduced halogen headlights (H4) with combined high-beam and low-beam bulbs. As with the double-filament bulbs that preceded them, the light was produced by a glowing tungsten wire. In halogen lamps, however, the glass bulb was filled with a halogen gas (iodine or bromine). This produced a higher and more constant light output and increased the service life of the lamp.

As an advancement of the transistorized ignition (TSZ), the breakerless TSZ-i is equipped with an electronic ignition impulse sensor, making it a completely maintenance-free system. As well as the previous maintenance work, the need to replace the mechanical contacts is also a thing of the past. At the same time, the precision of the TSZ-i allows the ignition to be integrated in electronic engine management systems (Motronic).

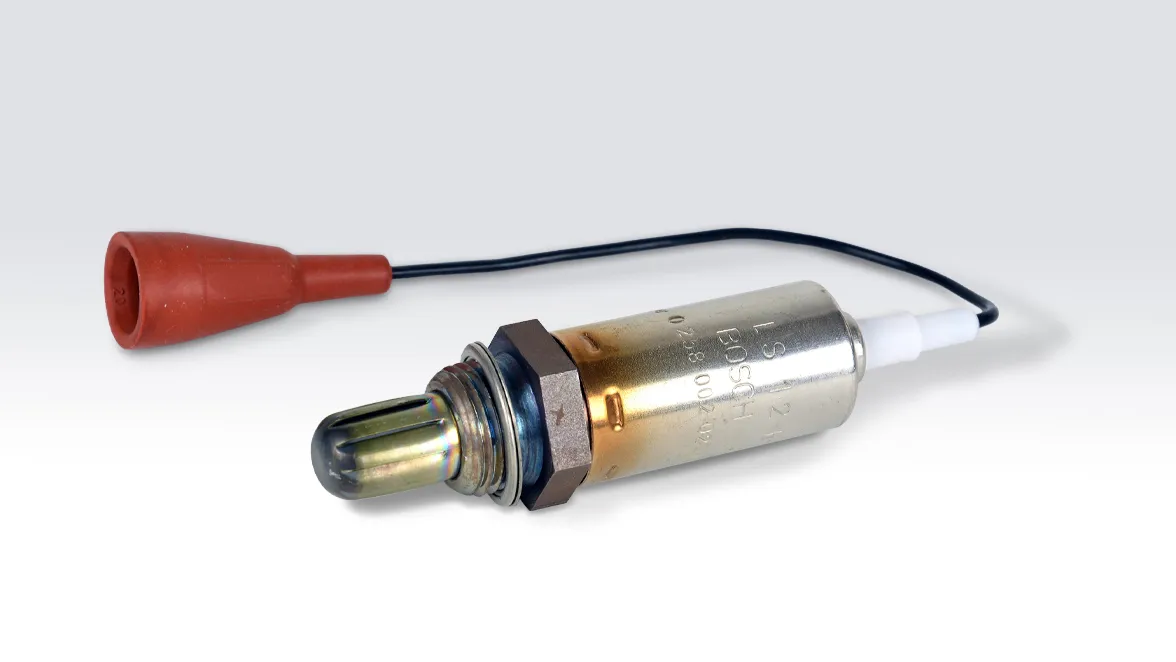

The lambda sensor is one of the main components of three-way catalytic converters. It measures the oxygen content of the exhaust gas before it enters the catalytic converter. Based on the data supplied by the sensor, the electronic injection control varies the composition of the air/fuel mixture to maximize the combustion efficiency and enable optimum exhaust gas treatment by the catalytic converter.

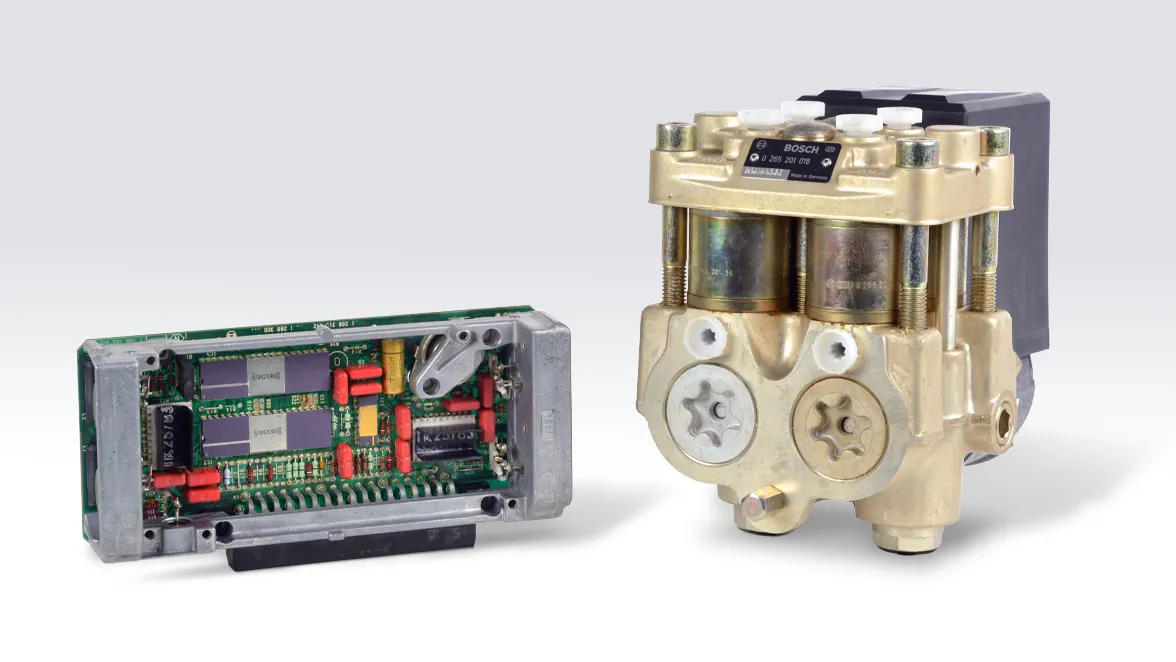

The ABS success story began in 1978 when production of the first electronically controlled antilock braking system for four-wheeled passenger cars commenced after nine years of development. If the wheels lock up, ABS reduces the brake pressure and raises it again up to 40 times per second. This ensures short braking distances, even on slippery surfaces, and allows the driver to retain control of the vehicle.

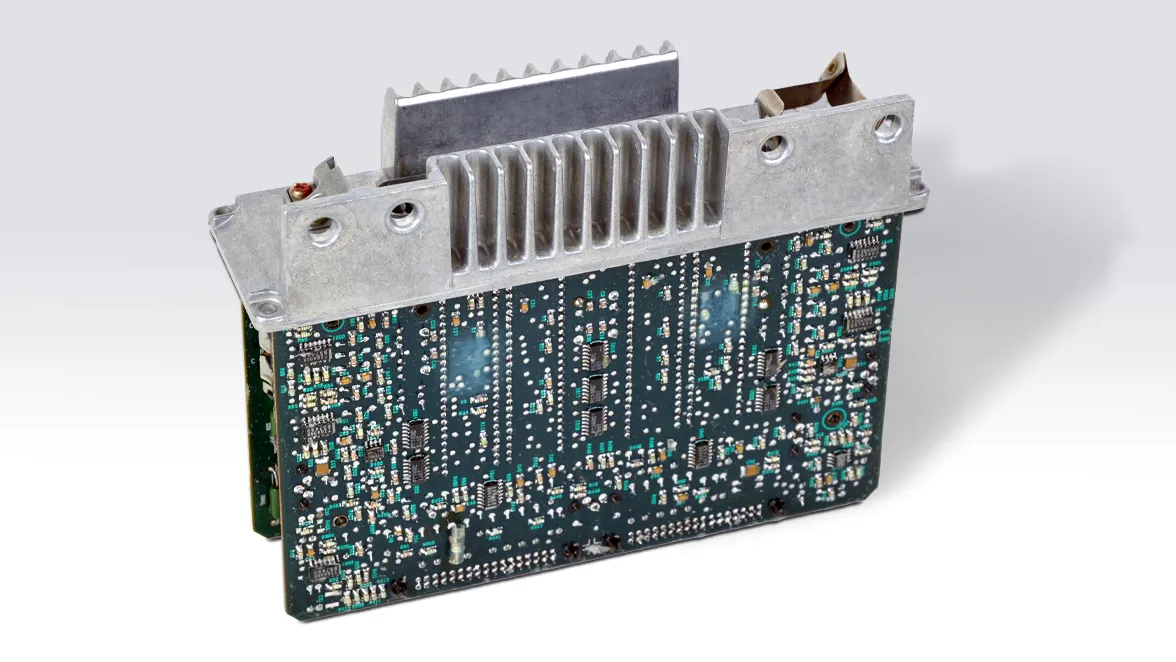

Motronic was the world’s first electronic gasoline injection and ignition system with a shared control unit to enter volume production on a large scale – and it represented the first use of the microprocessor in a car. It controlled parameters such is the injection quantity and ignition timing based on a wide range of criteria, such as the accelerator pedal position and engine temperature, all of which had to be recalculated with every ignition process. This resulted in optimizations across the board, particularly with regard to fuel consumption, emissions, and engine refinement. The first production vehicle to be equipped with Bosch Motronic was the BMW 732i.

The occupant protection systems based on the airbag control unit minimize the acceleration and forces acting on the vehicle occupants in the event of an accident. The airbag control unit does this by evaluating data from the pressure sensors for side impact detection as well as from the acceleration sensors for side, front, and rear impact detection.

The invention of the navigation system: EVA was the first experimental system for autonomous navigation. It featured a digital map with destinations converted into numeric codes. Once the driver had entered the start and destination coordinates, EVA automatically calculated the best route. Wheel sensors detected the travel paths and changes in direction and compared the vehicle’s movements with the selected route.

The traction control system prevents the driven wheels from spinning. The electronic control unit reduces the speed of spinning wheels until they regain traction. TCS is an early example of connectivity between different electronic systems within a vehicle.

TravelPilot IDS was able to inform the driver of their exact position based on a digital map, entry of start and destination coordinates as well as wheel sensors. The commercial breakthrough occurred in 1995 with the TravelPilot RG 05, which featured satellite-assisted navigation, route guidance, and speech output.

Abbreviation for “light electronic.” Gaseous-discharge lamp for headlights. Litronic generates significantly more light output than halogen lamps but with lower energy consumption. The light has a high color temperature, similar to sunlight, but with large amounts of blue and green.

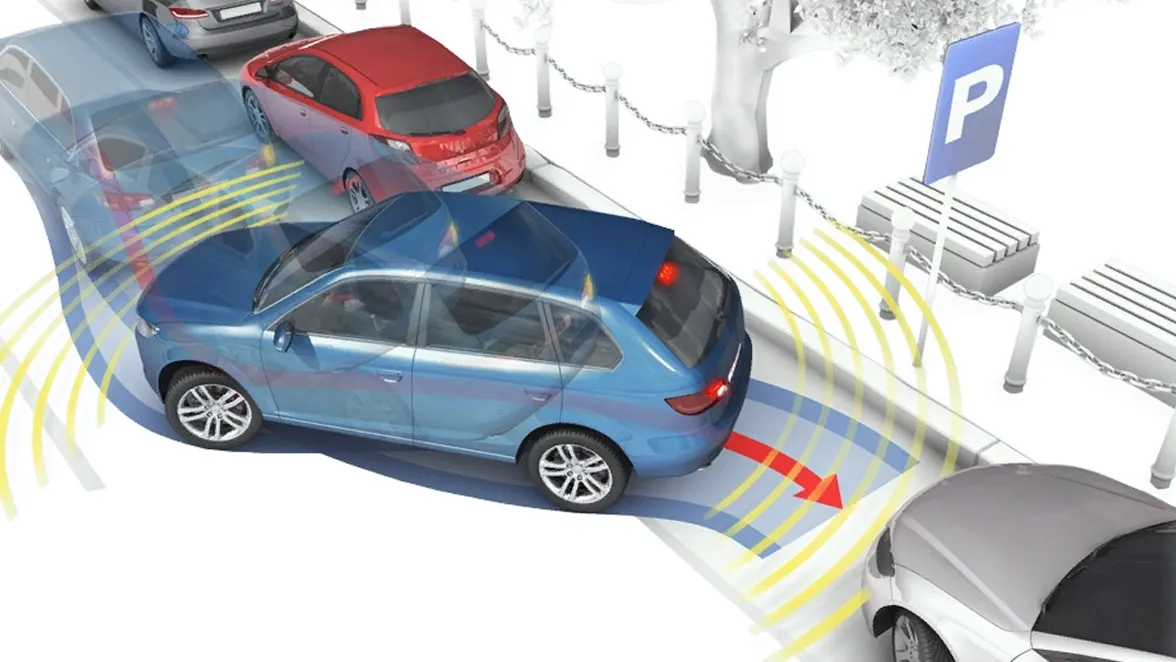

The parking aid makes vehicle parking a much easier proposition. It effectively prevents vehicle damage, particularly in tight spaces. Sensors in the rear bumpers emit ultrasonic signals and receive their echoes. The system then uses the time difference to measure the vehicle’s distance from the obstacle and informs the driver by means of visual or audible signals. As a result, even the smallest parking spaces become accessible to the driver.

This systems assists drivers in virtually all critical driving situations. It combines the functions of the antilock braking system (ABS) and traction control system (TCS), but can do considerably more. It also detects and actively counteracts vehicle skidding movements. This raises driving safety significantly.

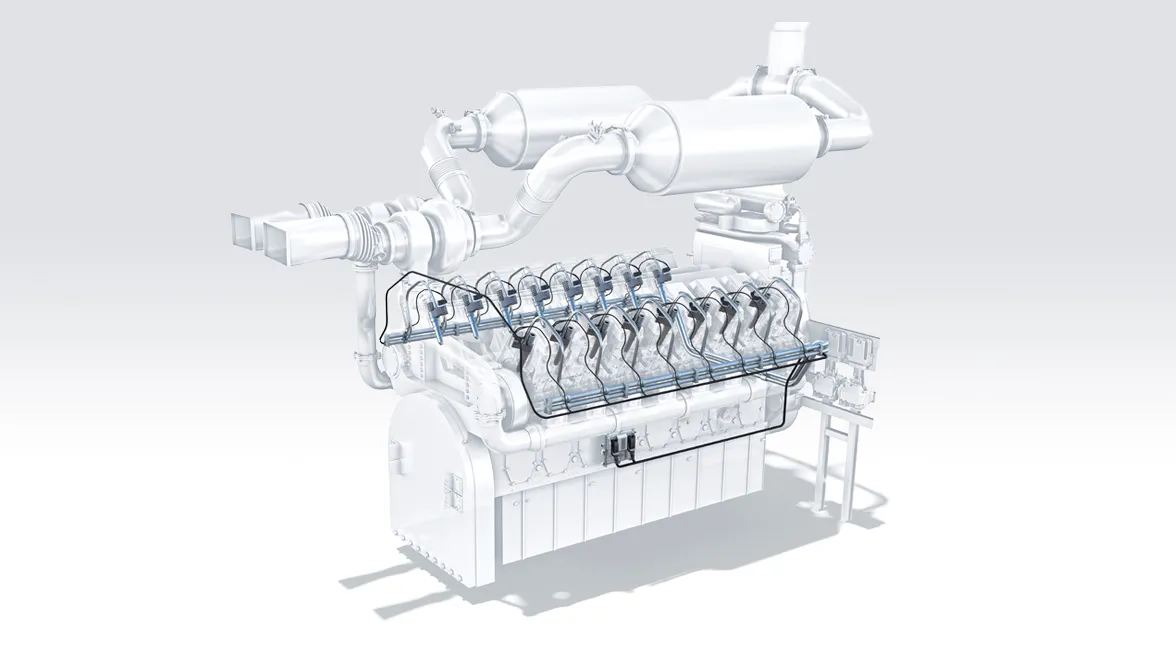

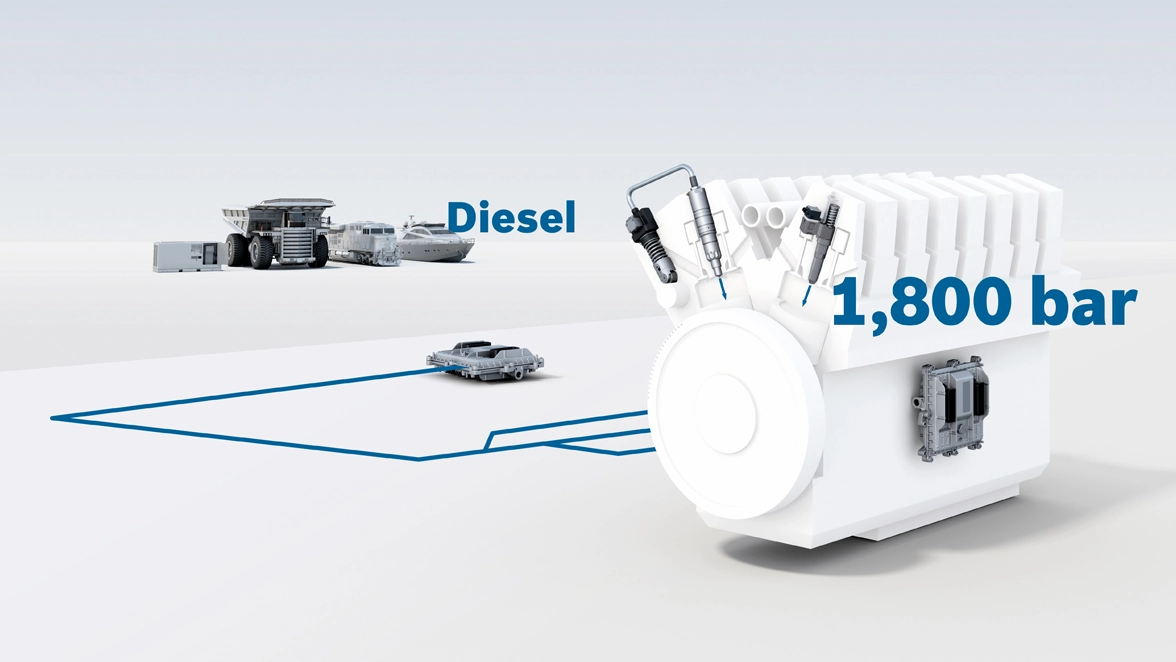

In contrast to conventional systems such as in-line or distributor pumps, the fuel mixture is stored under high pressure to enable up to eight injections per cycle, which has a significant impact on engine refinement. Thanks to the common-rail system, vehicles release 96 percent fewer emissions than 20 years previously, while the lower consumption also reduces vehicle CO₂ output by a considerable margin.

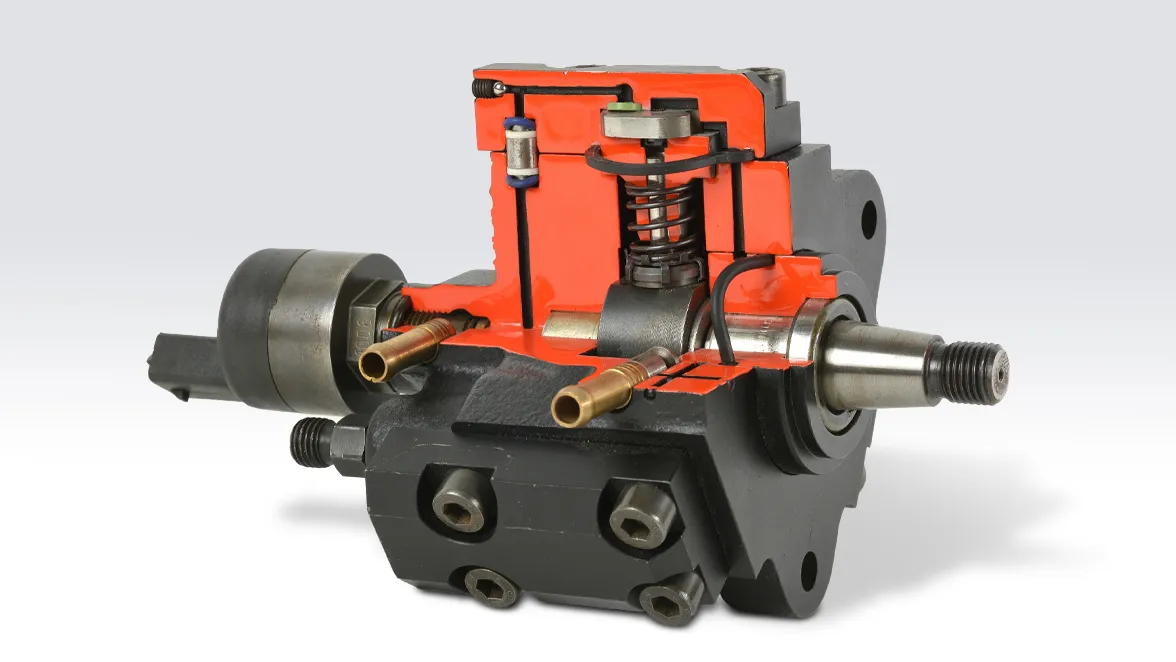

The unit pump injection system (UPS) injects the fuel into the engine cylinder. It consists of an electronically controlled unit pump (UP) and a nozzle holder assembly connected via a precisely adapted high-pressure line. The unit injector system is a nozzle holder assembly with integrated high-pressure pump.

This is a three-cylinder radial piston pump that is powered by the intake camshaft. The three pump elements are positioned at 120° intervals and minimize the pressure fluctuations in the fuel rail. Fuel pressures of up to 100 bar could thus be generated. Modern systems today reach pressures of more than 350 bar.

The EHB system dispenses with the hydraulic connection between the actuation unit and the wheel brake. The pedal pressure and speed are detected by sensors and combined with other signals from the electronic control unit to calculate the brake pressure, which is then generated by the hydraulic unit with its electric high-pressure pump.

Depending on the driving situation, the piezo injector injects the necessary fuel quantity for efficient combustion into the cylinder. It is continuously supplied with fuel by the rail via the high-pressure connection. The injection process is initiated by the electronic control unit via the electrical connection.

The active infrared night-vision system from Bosch provides the driver with a three times greater field of vision than conventional low-beam headlights, without dazzling other road users. Two infrared headlights illuminate the road with light beams that are invisible to the human eye. A video camera installed behind the front windshield records the scene ahead and transmits the video data to a display in the instrument cluster or to the central display via an electronic control unit. The display then provides the driver with a clear black-and-white image of the traffic situation.

The internal-combustion engine is switched off automatically when the vehicle is stationary. To resume driving, a simple tap of the accelerator pedal is sufficient to restart the engine. This warm start uses the same amount of fuel as 0.7 seconds of engine idle. This makes every stop more than worthwhile from the very first second – both for humans and the environment.

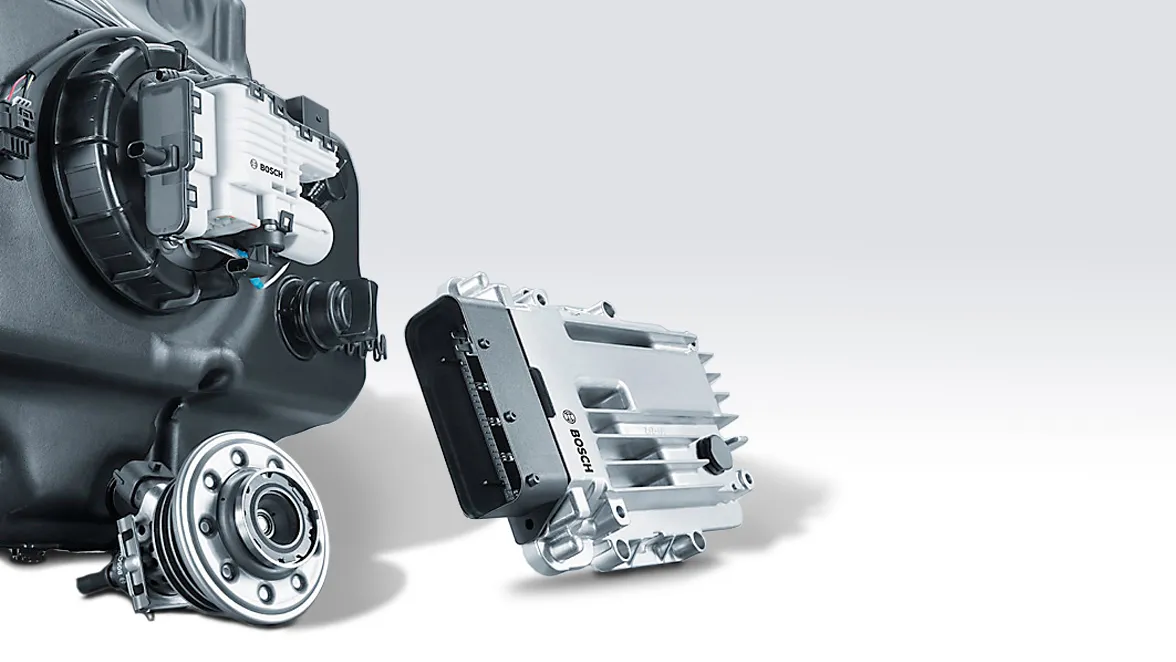

The Denoxtronic metering system is used to inject AdBlue®, an aqueous urea solution (32.5%), into the exhaust gas flow. The urea is converted into ammonia through thermolysis and hydrolysis. In the SCR catalytic converter, the ammonia reduces the nitrogen oxides to water and nitrogen.

An ultrasonic sensor scans the edge of the road as the vehicle drives past. When the park assist function detects a suitable parallel or perpendicular parking space, it informs the driver immediately. If the driver then presses the button to activate the park assist, the system calculates the optimum path into the space as well as the necessary steering movements and the number of maneuvers needed. Then the park assist takes control: the driver lets go of the steering wheel and controls the parking maneuver by carefully accelerating and braking.

In this system, modern control technology manages the interplay between the internal-combustion engine and electric machine. No mechanical power splitting takes place. One of the main advantages of this system is its simple design. Its first use in volume production was in the Volkswagen Touareg and Porsche Cayenne S.

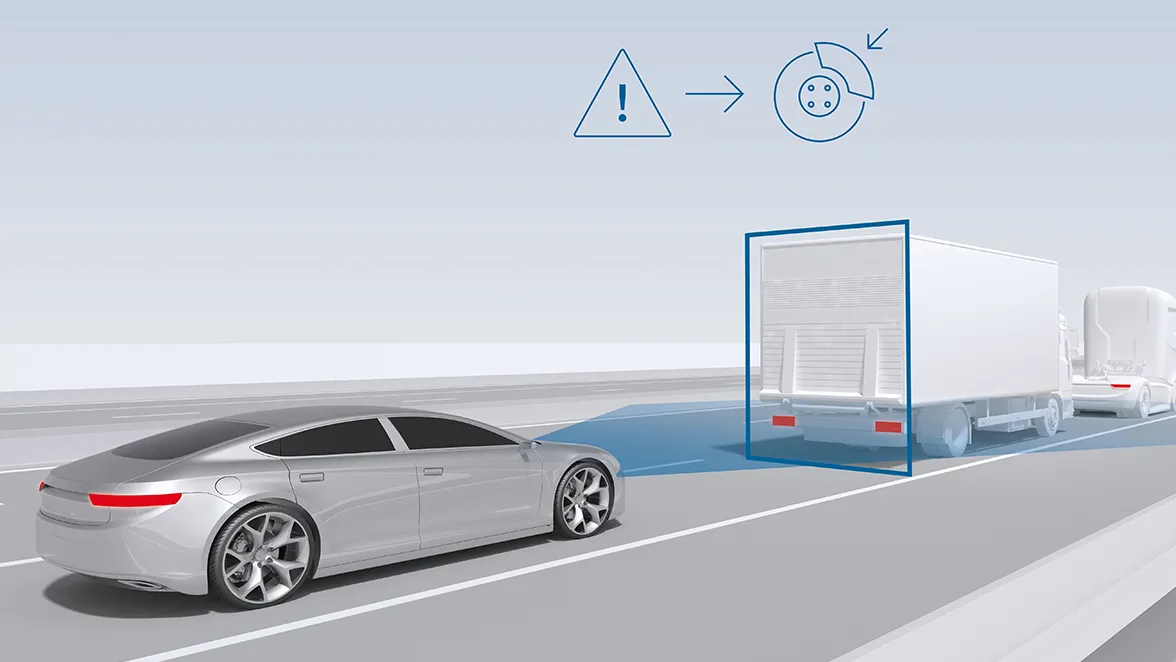

To reduce the risk or at least mitigate the effects of an accident in heavy traffic or when turning at an intersection, Bosch has developed the automatic emergency braking system. If the system detects critical proximity to a stationary or moving vehicle ahead, it prepares the braking system for the possibility of an emergency stop and initiates partial braking in an emergency situation.

Bosch developed the eBike drive as a complete system from the outset, consisting of motor, software, sensors, battery and control unit. The gearbox arrangement ensures optimum integration and more ground clearance. This system approach with a compact mid-motor concept quickly caught on and made Bosch the European market leader in just a few years.

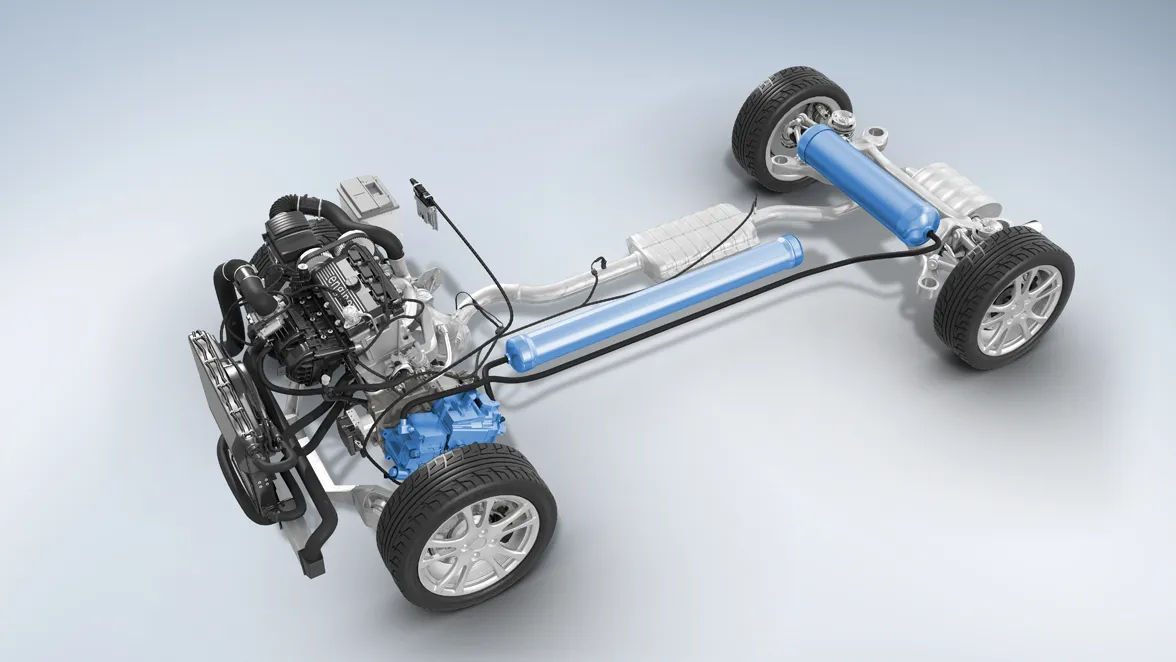

The hydraulic system consists of two hydraulic units along with the corresponding pressure accumulators. The kinetic energy that is normally lost as heat during braking, particularly in stop-and-go traffic, is instead stored in the hydraulic vessels. It can then be used to run the internal-combustion engine more efficiently during low load operation.

Motorcycle stability control uses a range of sensors to record the motorcycle dynamics and supports the rider on straight stretches and in corners as well as when accelerating or braking. This sensor data forms the basis for the brake control technology of MSC, which significantly increases safety and stability in all riding situations.

Electric steering is a key technology for assisted and highly automated driving. EPS controls and supports the steering of vehicles with the aid of an electric motor, which ensures an optimum and pleasant steering feel along with greater safety in the event of a fault thanks to the new generation of control units.

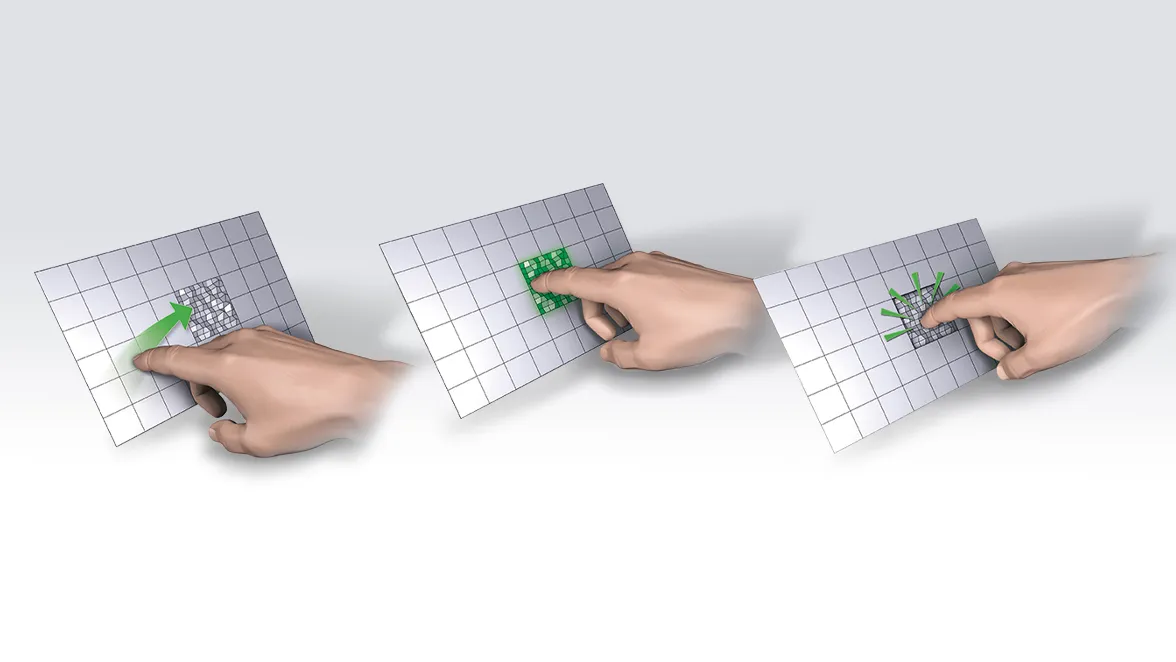

Real buttons on the screen feel and behave just like mechanical keys. The pressure-sensitive display enables new forms of interaction: surface structures can be perceived as rough or smooth, while edges and surfaces can be displayed dynamically and according to the position of the user’s finger on the screen.

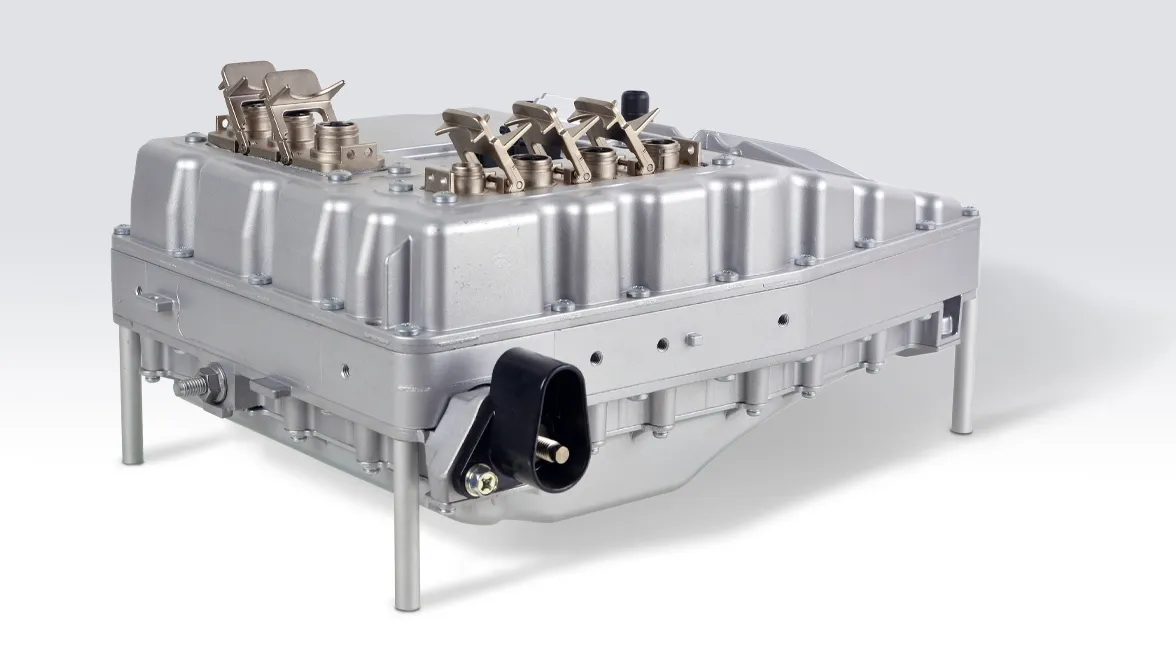

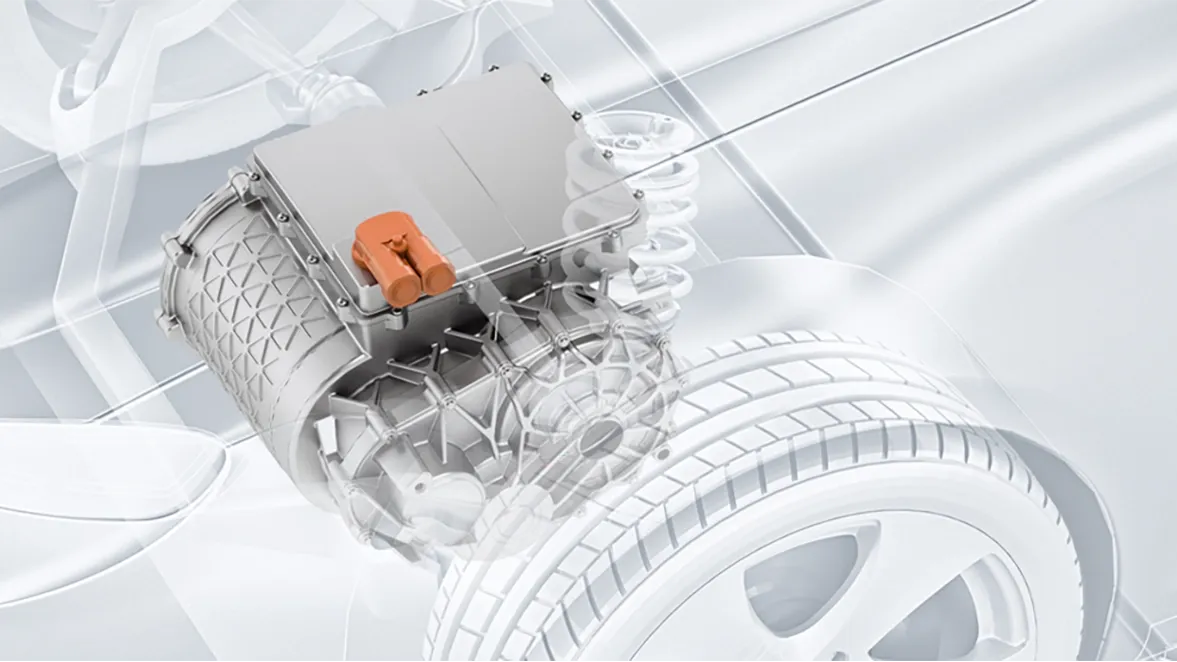

The electric motor, power electronics, and transmission are combined to form a single unit that drives the vehicle axle directly. This reduces the complexity of the electric drive and makes the powertrain more affordable, compact, and efficient.

e-bike ABS from Bosch enables more efficient braking. Wheel speed sensors on both wheels recognize when the brakes lock up, and the braking force is adjusted automatically via software and control intervention. This reduces the risk of falls on slippery ground or of being thrown over the handlebar on slippery surfaces.

Large side mirrors on commercial vehicles restrict forward visibility and result in high aerodynamic drag. The digital vision system replaces the external side mirrors with two interior monitors and two external cameras, which are mounted above the driver’s cabin. The aerodynamic design reduces fuel consumption by up to two percent. At the same time, the system improves the driver’s all-around view significantly and minimizes blind spots.

This is the world’s first fully automated and driverless parking function (SAE Level 4). It not only takes the hassle out of searching for a parking spot but also handles the actual task of parking the car in the parking garage. The driver simply leaves the vehicle in the designated drop-off area, and the smart Bosch infrastructure installed in the parking garage then takes over and interacts with the technology in the vehicle to drive it to the vacant space and park it.

The absence of an electronics box makes the charging cable much lighter and more compact than conventional charging cables. An adapter allows the driver to select the right plug for the available charging point. This allows the hybrid or electric vehicle to be charged both from a conventional domestic electrical outlet or from a wall charger when at home or at a charging station when on the road.

Semiconductors made from silicon carbide (SiC) are small, powerful, and extremely efficient. Power semiconductors made from silicon carbide enable highly efficient use of the available energy. In the power electronics of electric vehicles, silicon carbide chips allow drivers to travel much further on a single battery charge – around six percent on average when compared to their silicon counterparts.

The cockpit & ADAS integration platform is a scalable, modular platform. It combines the system functions for assisted and automated driving and infotainment in one high-performance computer. Thanks to this capability, this Bosch vehicle computer can simultaneously detect lanes, park automatically, and process smart, personalized navigation and voice assistance functions.

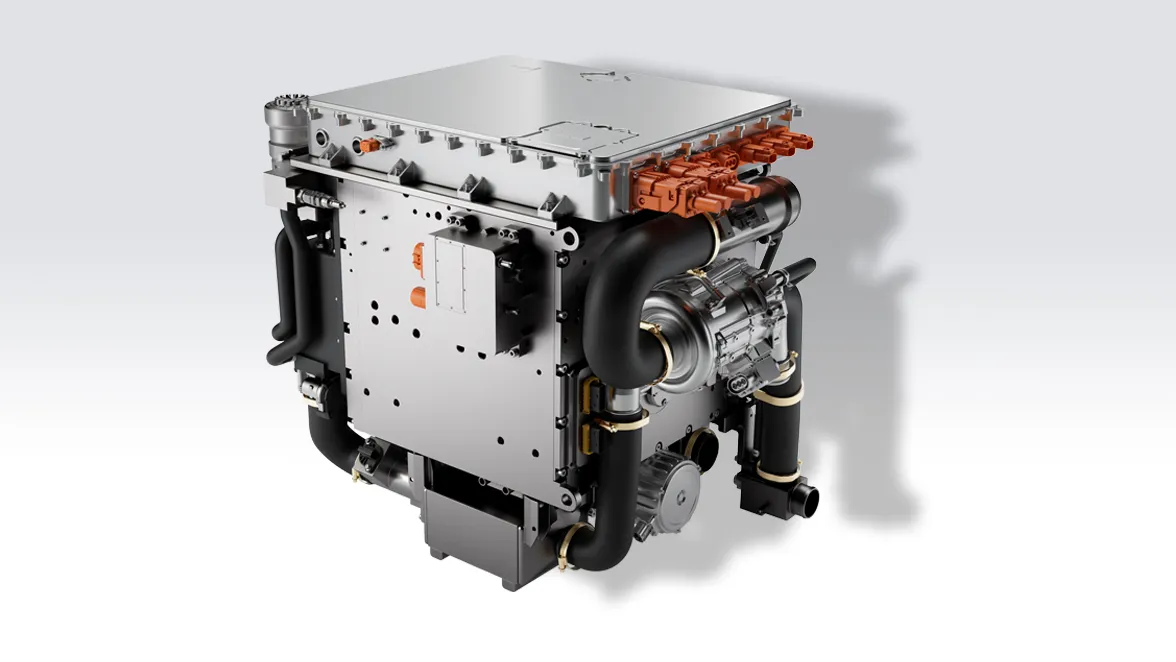

The scalable fuel cell power module is a fuel cell system that generates electricity from hydrogen in vehicles. It is primarily used in commercial vehicles, especially in long-distance applications. The system comprises a fuel cell stack and the fuel cell submodules, such as those for hydrogen and air, which are required for the stack to operate.

Are you interested in our solutions? Then write us a message. Our sales team will be happy to help you.

Start enquiry